Criteria for sewage pipeline rehabilitation technology selection

The optimal rehabilitation method can be selected only after collecting exhaustive knowledge of the sewer’s condition, so before preparing the technical documentation the Contract has to perform preparatory works.

The scope of the preparatory works includes:

- basic information about the existing sewer: type of sewer, diameter, the material it is made of,

- technical condition of the sewer impacting the functional properties,

- conditions impacting the installation process,

- subsurface and groundwater conditions,

- horizontal layout of the sewer,

- required internal and external load strength,

- requirements related to hydraulic flows,

- required durability,

- number of house drains for rehabilitation,

- degree of ovalization and diameter variations,

- radial displacement (faults at connections),

- axial displacements,

- cracks, collapsed, abraded, and corroded points,

- access to the existing pipe,

- motorized and pedestrian traffic,

- proximity of other networks,

- changes of direction,

- connections and branching,

- ensuring continuous operation of the pipeline,

- length of specific sections.

Static strength calculations according to ATV-DVWK – A127P

General assumptions for hydraulic calculations

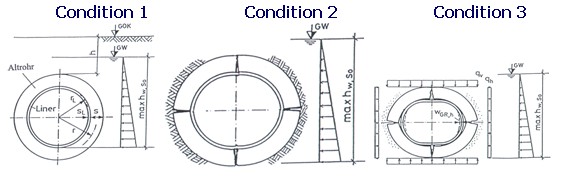

Control calculations for use of tight-fit liners, cured-in-place liners, segmental liners and mineral coating.

The following materials have been used in the calculations:

- German collection of ATV rules: DVWK, ATV-A110P guidelines,

- Guide „Urban sewer systems and wastewater treatment plants” by Karl and Klaus R. Imhoff, 1996 edition.

Flow calculations will be made according to the Manning formula:

Q = (1/n) * R(h)2/3 * i1/2 * F [m3/s]

assuming full loading of the sewer line (flow capacity).

For circular sewer lines the hydraulic radius is:

Rh = 0,25 * D [ m ]

For sewer lines with oval cross section the hydraulic radius is:

Rh = 0,579 * r

For sewer lines with bell-shaped cross section the hydraulic radius is::

Rh = 0,424 * r

where:

n - roughness coefficient

Rh - hydraulic radius [m]

i - longitudinal drop of the sewer line [%o]

F - cross section [m2]

B - width of the sewer line [mm]

H - height of the sewer line [mm]

r - 1 B

D - diameter of the sewer line [mm]

The following assumptions are applied:

- for old sewer lines made of concrete n = 0.0150, and for brick n = 0.0160, while for new sewer lines the roughness coefficient is assumed to be the value characterizing the material used,

- longitudinal drop of an equivalent pipeline section matching its actual run.

Static strength calculations

Assumptions for static strength calculations will be applied according to German ATV-DVWK rules.

ATV-DVWK is a German Association for Water Management, Wastewater and Waste Engineering, which manages and coordinates work of specialists dealing with water management, wastewater treatment and waste handling. The following ancillary materials have been used in rehabilitation of sewer lines: ATV-DVWK – M127P – Part 2 „Static strength calculations for technical rehabilitation of sewer lines by introducing liners or using installation methods” dated January 2000. The Ancillary Materials have been developed in result of an honorary participation of the working group and are based on joint scientific and technical works of its members. They contain methodology of making calculations for rehabilitation using cured-in-place liners, tight-fit liners, segmental liners and spiral-wound liners.

Acceptance procedures

Acceptance procedures for the works are based on provisions of PN-EN 1610 „Construction and testing of sewer lines”. Moreover, acceptance of every sewer section will include supplying the following documents:

- Draft of the section,

- Footage from sewer inspection done using a sewer camera before its rehabilitation,

- Monitoring report,

- Offsets for existing house drains,

- Reports with sewer rehabilitation technology approved by the Contract Engineer,

- Leak proof test reports,

- Subcontractor footage recorded using a sewer camera,

- Photo documentation of house drain rehabilitation,

- Compliance statements for the materials used.